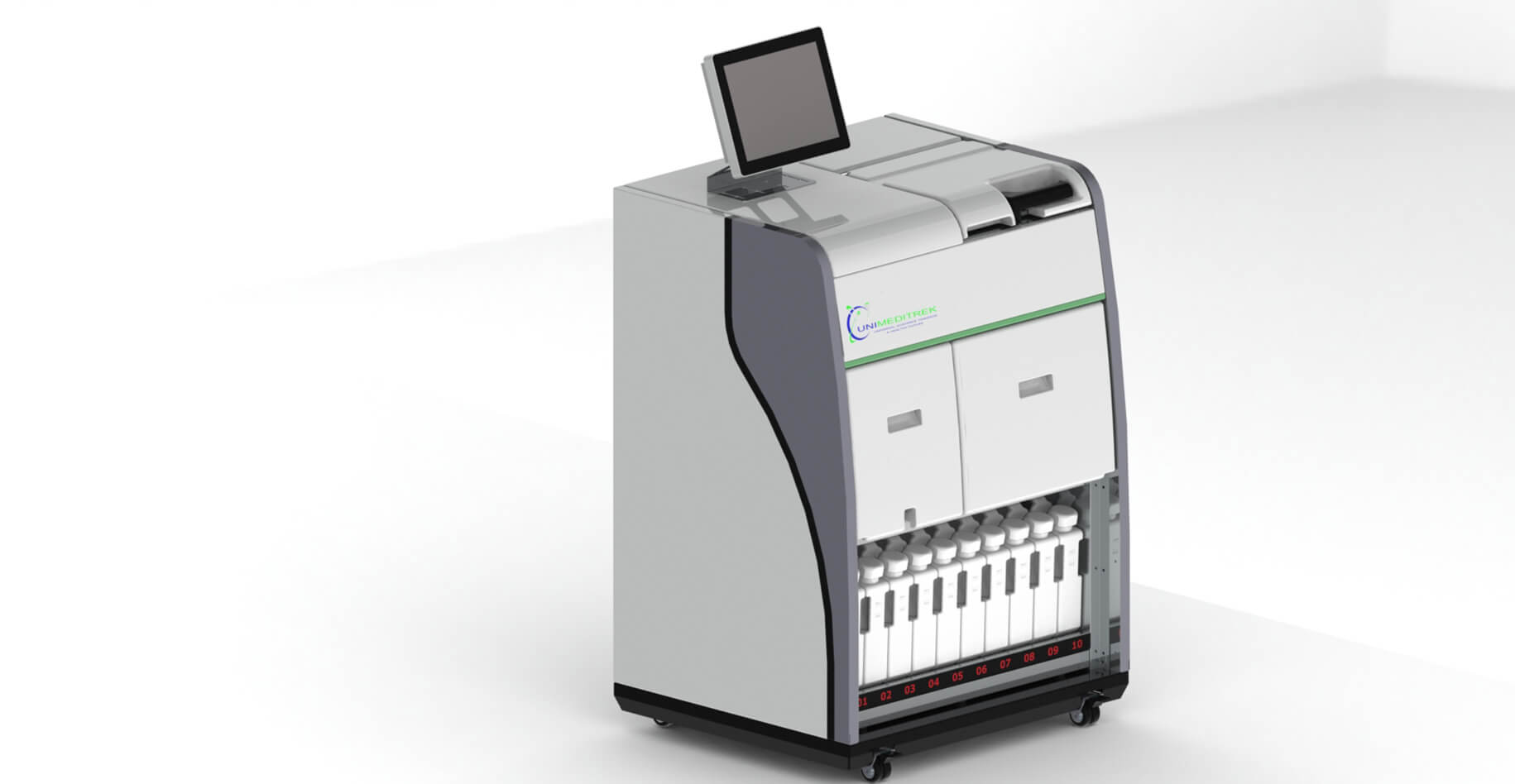

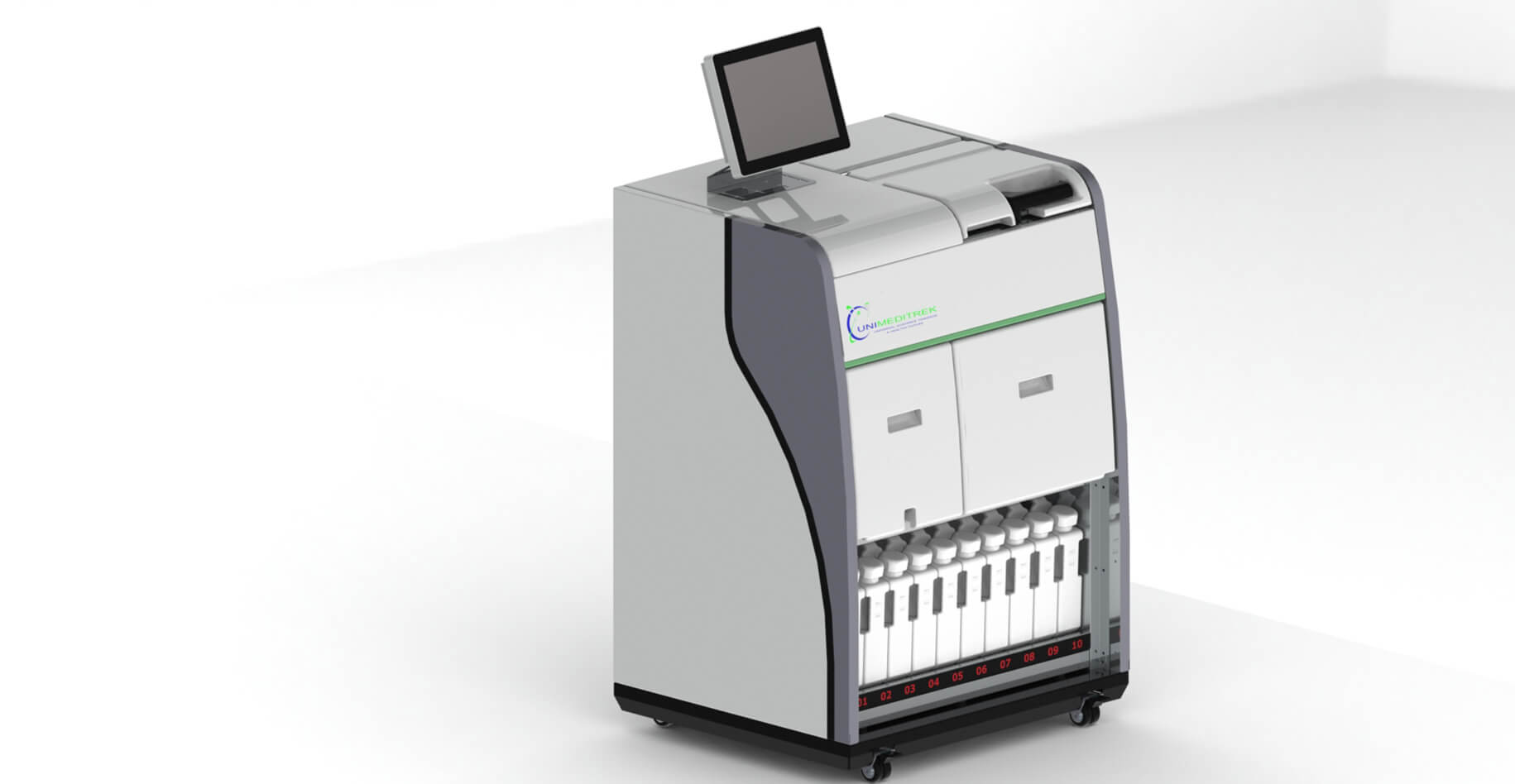

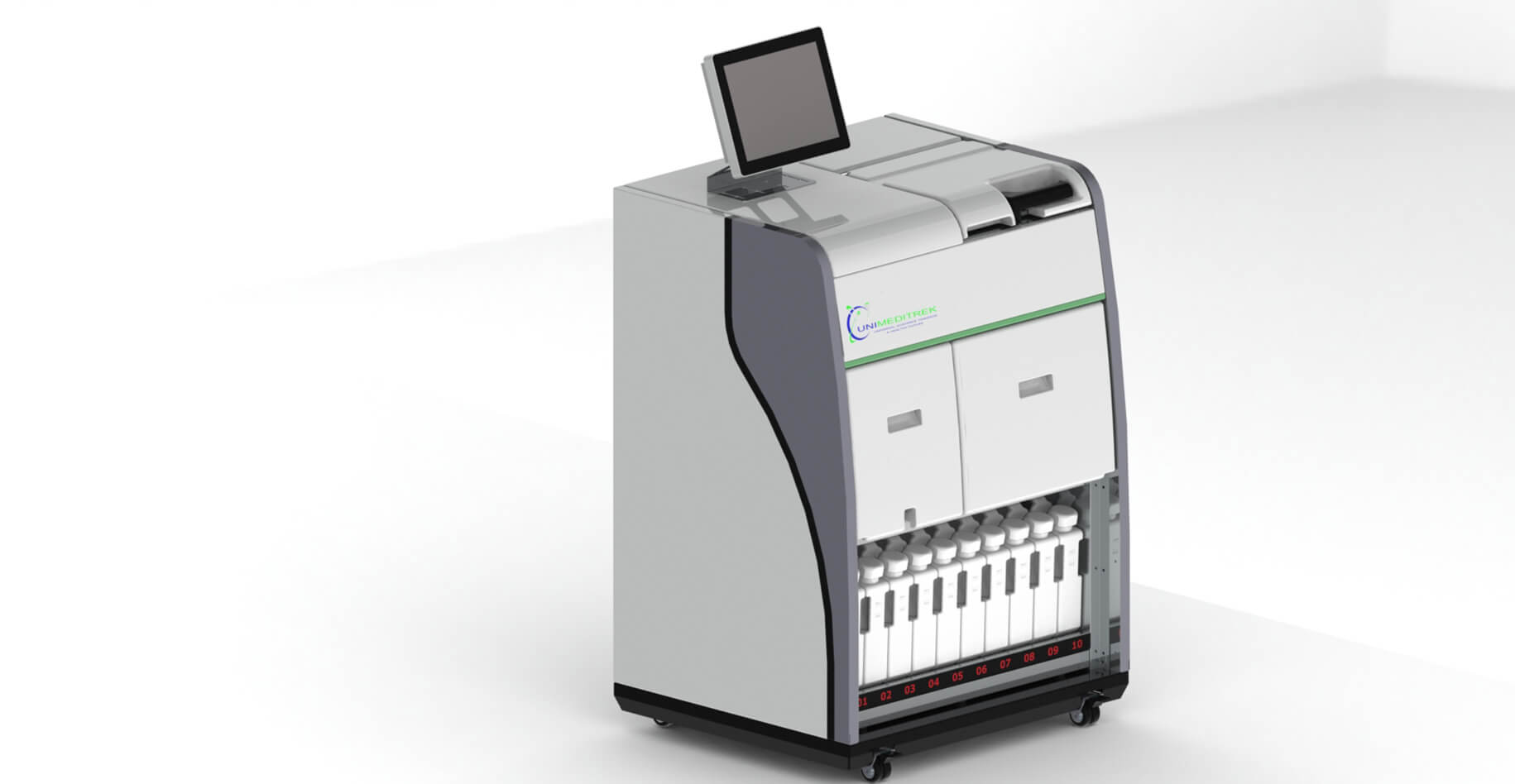

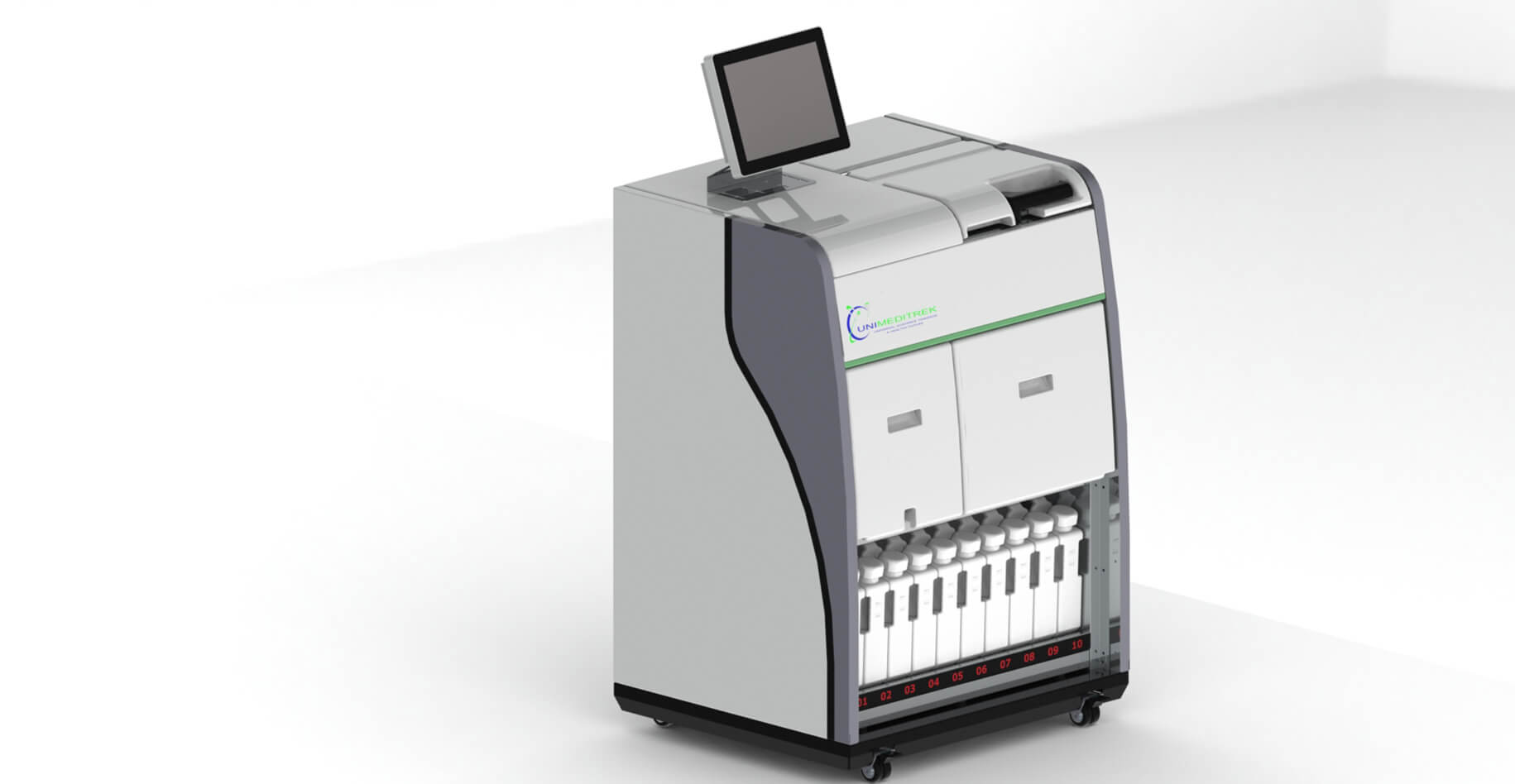

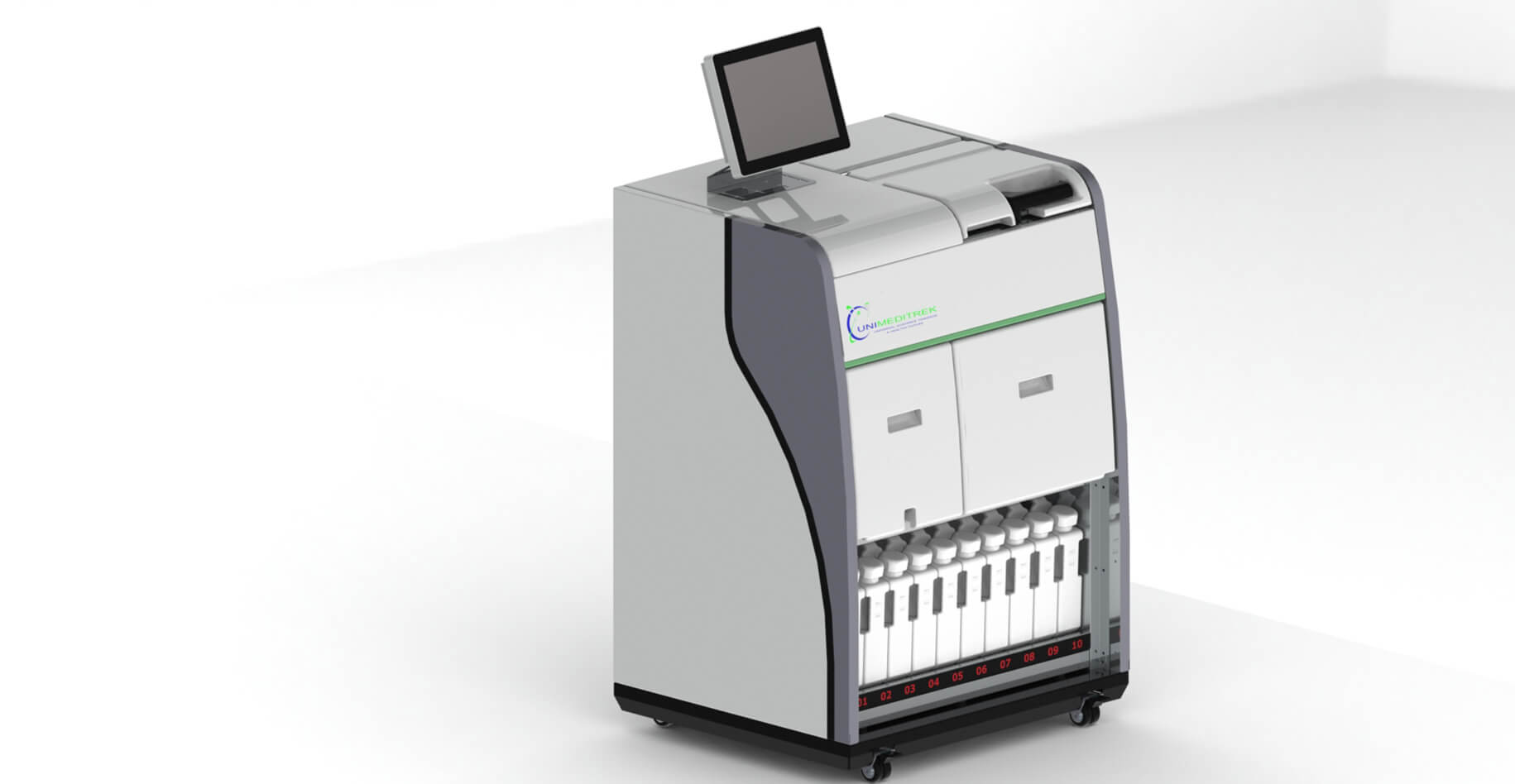

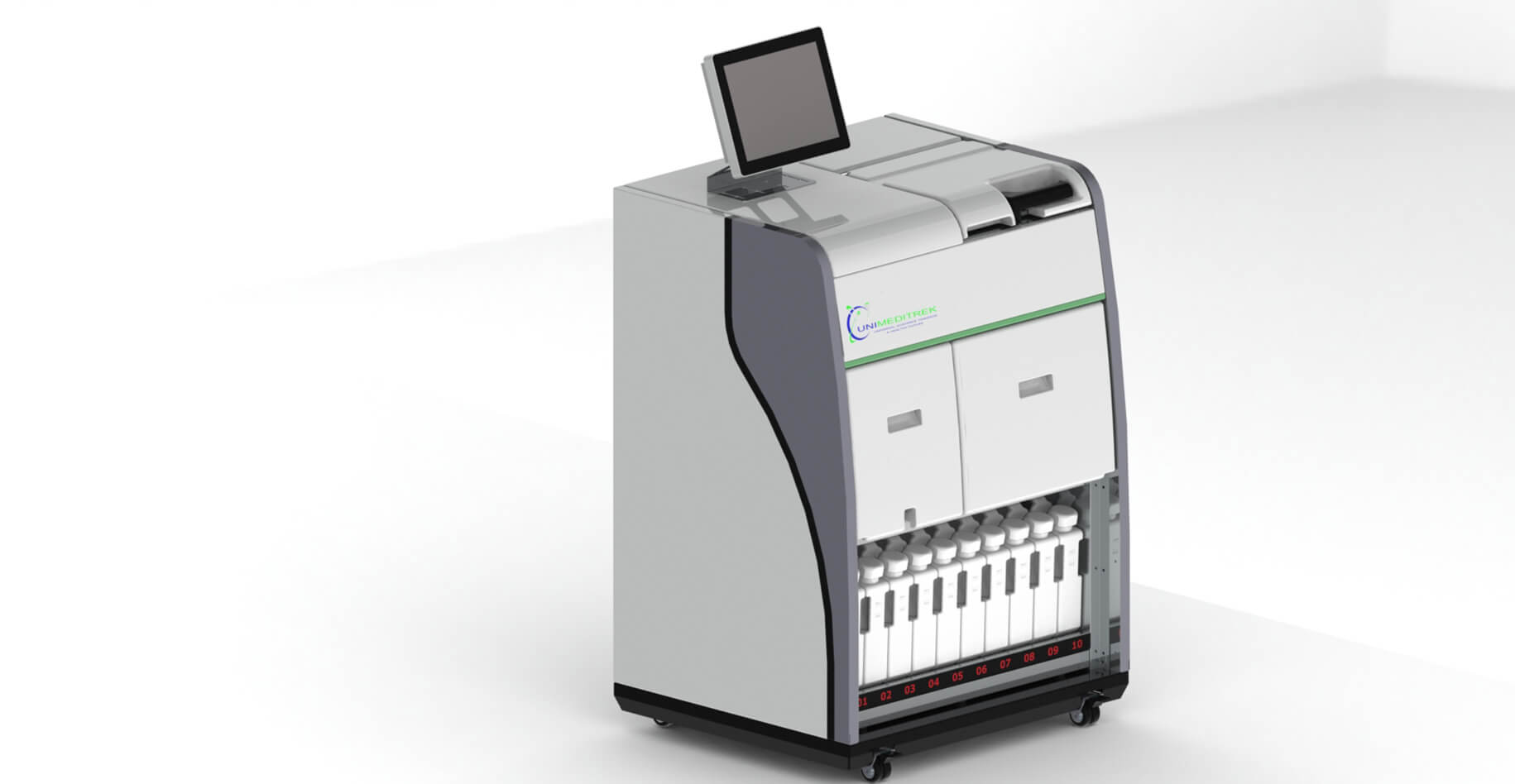

Unimeditrek Kshirom Series VTP 300 sets new standards for achieving finner specimen processing on each run. An open system capable of using standard cassettes form open market. This latest state-of-the art technology equipment can be updated remotely by our expert technician for all the late enhanced processing/monitoring techniques formulated by our continuous research and development work.

Unimeditrek Kshirom Series VTP 300 is an elegant processor for paraffin infiltration of tissue, intended for everyday clinical and research histopathology. Unimeditrek's Processor is designed, keeping in mind simplicity of use coupled with rich user interface experience for the user. It offers may unique features like Reagent Management System, and a one click start of user defined Favourite Programs and at the same time offers advance Specimen processing results with value for money. Unimeditrek VTP 300 uses all high and components from the top compo ent manufacturers around the world coupled with admirable engineering and manufacturing technology, which in return helps us offer our customers with a product with the maximum uptime in the world market.

Straight forward to learn and run user interface with solvent-resistant color touchscreen.

Easy to use software with context-sensitive online help feature.

Remote Service for real time application and service support.

Extensive safety system with inventive reagent compatibility check.

Instrument performance control.

Remote Fill and Drain Feature.

Superior Reagent Management System (RMS).

Accurate temperature control and reagent agitation

Vigorous paraffin cleaning program.

Vigorous SPC cleaning program.

Two-level password security.

Complete documentation options.

Sturdy construction, which integrates revolutionary technology

Inbuild over temperature/overpressure/over vacuum protection.

User can run rapid biopsies during the day for fastprocessing & conventional programs overnight.

Possibility of interrupting an automatic process for reloading or removing cassettes.

Easy editing & changing of programs, even during processing run.

User Progammable agitation vertical & horizontal (Air Budding Technology) can be turned on/off and time for agitation is user defined.

Process run screen displays all the parameters on LCD touch screen like current date, time, finish date & time, all zone temperature & pressure, cycle, current reagent

Auto restart function

Compatible with xylene free solution Proprietary technology to check & take user commmand for low reagent levels/poor bottle connection before start of program.

In build unlimited memory run/error log.

Locking facility to avoid inadvertent operation.

Straight forward to learn and run user interface with solvent-resistant color touchscreen.

Easy to use software with context-sensitive online help feature.

Remote Service for real time application and service support.

Extensive safety system with inventive reagent compatibility check.

Instrument performance control.

Remote Fill and Drain Feature.

Superior Reagent Management System (RMS).

Accurate temperature control and reagent agitation

Vigorous paraffin cleaning program.

Vigorous SPC cleaning program.

Two-level password security.

Complete documentation options.

Sturdy construction, which integrates revolutionary technology

Inbuild over temperature/overpressure/over vacuum protection.

User can run rapid biopsies during the day for fastprocessing & conventional programs overnight.

Possibility of interrupting an automatic process for reloading or removing cassettes.

Easy editing & changing of programs, even during processing run.

User Progammable agitation vertical & horizontal (Air Budding Technology) can be turned on/off and time for agitation is user defined.

Process run screen displays all the parameters on LCD touch screen like current date, time, finish date & time, all zone temperature & pressure, cycle, current reagent

Auto restart function

Compatible with xylene free solution Proprietary technology to check & take user commmand for low reagent levels/poor bottle connection before start of program.

In build unlimited memory run/error log.

Locking facility to avoid inadvertent operation.

| Maximum capacity – | ||

| Metal basket | : | 300 cassettes approx |

| Retort material | : | stainless steel |

| Level sensing | : | optical sensors with digital display (optional) |

| Processing retort volume temp | : | 4 liters/ambient to 75°C |

| Paraffin temperature range | : | ambient, 30-75° C (User set limit) |

| Reagent temperature range | : | ambient, 30-60° C |

| Temperature accuracy | : | +/— 1 C |

| Vacuum & pressure options | : | 4 (V/P, V, P, Ambient) |

| Vacuum | : | 70 kPa (g) |

| Pressure | : | +35 kPa (g) |

| Recirculation (pump in/out) – | ||

| Time before first cycle | : | 12 minutes |

| Time between cycles | : | 20 minutes |

| Incubation time | : | 0-99 hours |

| Delayed end-time | : | 59 minutes programmable, up to one week |

| Number of paraffin baths | : | 4+1, connected directly to the retort |

| Paraffin bath volume | : | 3 liters each |

| Average paraffin melting time | : | approx. 10 hours |

| Number of reagent bottles | : | 10 |

| Reagent bottle volume | : | 3 liters each |

| Clean cycle bottles | : | 2 |

| Overall dimensions (D x W x H) | : | 720 x 600 x 1060 cm |

| Weight (instrument only) | : | 150 kg approx |

| Display | : | Color touchscreen,solvent-resistant |

| Reagent Management System | ||

| Remote fill and drain system | ||

| Remote paraffin drain system | ||

| Two external alarm connections | ||

Tissue processing is a critical step for preparing samples for histopathological analysis. Getting the specimen right before processing is a crucial factor as as fresh specimens are delicate, and mishandling can potentially lead to sample loss. A typical room temperature tissue processing of 3 mm sample requires approximately 12 hours (Fixation: 10% formalin (120 min), alcoholic formalin (60 min, 60 min); Dehydration: 95% alcohol (60 min, 45 min), absolute alcohol (60 min); Clearing: xylene 60 min, 60 min; Infiltration: paraffin (30 min, 60 min, 90 min)).

The samples once procured should be immediately fixed if possible, or as soon as they are received after being transported. Key factors to consider during fixation include temperature, size of storage container, volume ratio of the fixative, pH, salt concentration, and incubation time. The choice of fixing solution depends on the detected antigen. Acetone and alcohol are used when precipitating fats and sugars and for maintaining immunologic competence;aldehydes (formalin [10% neutral buffered], 4% paraformaldehyde) are commonly used due to strong penetrability and less contractibility and background; and non-aldehydes are used in tissue fixation of peptide hormones.

Formaldehyde fixation is commonly performed at room temperature, and adequate volume of fixative in minimum1:20ratio for 3–4 mm thickness should be used in a container of appropriate size to avoid distortion of the fresh specimen and ensure good quality fixation.Isotonic buffers of pH 7.2–7.4 are recommended to avoid tissue swelling or shrinkage, and maintain ultrastructure with minimal distortion, and the duration of fixative exposure should be optimized for every specimen type.

The size and penetrability of the tissue determine the time required for this step.Insufficient dehydration of the sample can occur due to carry over of fixative into the processing alcohol. The presence of water in absolute alcohol stations before the clearing stations can also lead to incomplete dehydration. This residual water gets trapped during paraffin infiltration, resulting in soft samples that are difficult to cut in in microtomy. Conversely, over dehydrated tissue, due to prolonged alcohol step can be dry and hard to cut.

Toluene, xylene, and chloroform are the commonly used clearing agents, although xylene is less preferred due to its hazardous nature. Therefore, less toxic alternatives, such as isopropanol, have gained popularity. However, eliminating isopropanol during infiltration requires higher wax temperatures.

Paraffin based waxes are most commonly used and these are a mixture of paraffin wax and additives such as polyethylene or styrene. The wax used should be of good quality, as poor quality wax is unable to provide proper support to the tissue, resulting in blocks that are difficult to cut.Vacuum automated systems provide the advantage of rapid and efficient wax infiltration.

Using appropriate processing schedule

Appropriate schedule should be chosen depending on the tissue type and size; for example,less time is required for small endoscopic biopsy and more for large, fatty specimen.Over processed endoscopic biopsy samples become brittle can develop fine cracks throughout that are visible under microscope, which only becomes worse with poor microtomy technique. Under processed large fatty specimens appear fragmented under microscope and lack nuclear definition. Furthermore, specimens should be properly fixed to avoid zonal fixation, that occurs when the sample gets formalin fixedfrom outside and alcohol fixed in deeper areas, resulting areas of intact and hemolyzed cells. Nuclear streaming is another frequently observed phenomena that occurs when water in the tissue moves out too quickly, resulting in “squeezing” the cell, thus leaving a final appearance of the nuclei in a “streaming” configuration.Thiscommonly observed problemcan occur due to incomplete dehydration, too rapid dehydration, or processing solutions that are overused and in need of changing out.

Maintain reagent quality

Tissue processing reagents should be strictly replaced as per the guidelines. Ignoring these, such as using diluted or contaminated reagents, can result in poor processing quality; for example, old formalin bottles in cold storage can be identified with the presence of white paraformaldehyde deposits. Specimens can show poor preservation when heavily contaminated reagents are used well “out-of-threshold.”Bouncing out of the tissue samples, especially uterus and prostate samples, of paraffin block during microtome sectioning or nonadherence to the slides or block can be seen due to residual water in the tissue as a result of improper dehydration and paraffin infiltration, and changing reagents and re-processing the tissue samples is recommended. Processing reagents saturated with water and/or paraffin saturated with xylene or isopropanol can also result in greasy looking tissue that separates or “explodes” when ribbon is placed in the water bath.

Fresh tissue samples are delicate and require processing in a series of reagents to enable proper sectioning. Each of these steps should be customized depending on the tissue type and reagents used. Reagent quality and processing schedule are key determinants of the outcome of staining.

14 Chitra vihar,

New Delhi-110092, India

+919999579580

sales@unimeditrek.com